Introduction to Polyethylene and Polyethylene Wax

When exploring Polyethylene and Polyethylene wax, it quickly becomes clear that both materials play essential roles in modern manufacturing. Although they share the same polymer family, their behaviors differ greatly, and these differences matter significantly in real-world applications. Because industries depend on efficiency, durability, and performance, understanding how these materials function can help engineers, formulators, and manufacturers make better choices.

As a result, companies frequently evaluate these materials side by side to determine which one delivers the best results for their processes.

Table of Contents

ToggleWhat Is Polyethylene?

Polyethylene (PE) is widely known as the most used plastic in the world. As a thermoplastic polymer, it forms when ethylene undergoes polymerization. Moreover, depending on the production method, it can transform into various grades, such as:

-

LDPE (Low-Density Polyethylene)

-

HDPE (High-Density Polyethylene)

-

LLDPE (Linear Low-Density Polyethylene)

-

UHMWPE (Ultra-High-Molecular-Weight Polyethylene)

Because each type offers different mechanical properties, industries can select the grade that aligns best with their needs. Consequently, PE remains extremely versatile.

Anout Polyethylene Wax

Polyethylene wax (PE wax), on the other hand, is a low-molecular-weight form of PE. As a result of its shorter and more uniform chains, it behaves more like a hard wax than a typical plastic. Additionally, PE wax is well known for its:

-

Low melt viscosity

-

Strong lubricity

-

High hardness

-

Consistent melting point

-

Excellent thermal stability

Due to these properties, PE wax appears in coatings, adhesives, inks, plastics processing, rubber formulations, and polish products.

How Polyethylene and Polyethylene Wax Are Produced

Polymerization Process for PE

Polyethylene production relies heavily on polymerization. Depending on the catalyst system and reaction pressure, manufacturers can produce different grades:

-

High-pressure polymerization → LDPE

-

Ziegler–Natta catalysis → HDPE, LLDPE

-

Metallocene catalysis → precision molecular control

Because each method changes the branching of the polymer chains, PE grades exhibit different densities, strengths, and melt properties.

Production of Polyethylene Wax

Polyethylene wax, however, is produced through several distinct methods, including:

-

Direct polymerization, which yields high-quality PE wax

-

Thermal cracking, which breaks down long polymer chains into wax fractions

-

By-product recovery from other PE processes

Although each method produces usable wax, direct polymerization often creates the most uniform results. Consequently, it is the preferred method for high-performance applications.

Key Differences Between Polyethylene and Polyethylene Wax

Although both materials originate from ethylene, their structures and performance characteristics differ dramatically.

Molecular Structure Differences

PE typically contains long, strong polymer chains. Because of this, it behaves like a flexible plastic. Conversely, Polyethylene wax has significantly shorter chains, which cause it to behave more like a crystalline wax.

Thermal & Mechanical Properties

Because their molecular weights differ greatly, their physical properties vary as well.

| Property | Polyethylene | Polyethylene Wax |

|---|---|---|

| Molecular Weight | High | Low |

| Melting Behavior | Gradual | Sharp |

| Hardness | Moderate | High |

| Flexibility | High | Low |

As a result, PE is ideal for structural uses, while PE wax works best in lubrication and surface enhancement applications.

Processing Characteristics

While polyethylene softens slowly during heating, PE wax melts quickly and flows easily. Therefore:

-

PE wax improves lubrication

-

PE wax enhances pigment dispersion

-

PE wax reduces die buildup

-

PE wax increases surface smoothness

Meanwhile, PE remains the primary structural material in many plastic products.

Industrial Applications of Polyethylene and Polyethylene Wax

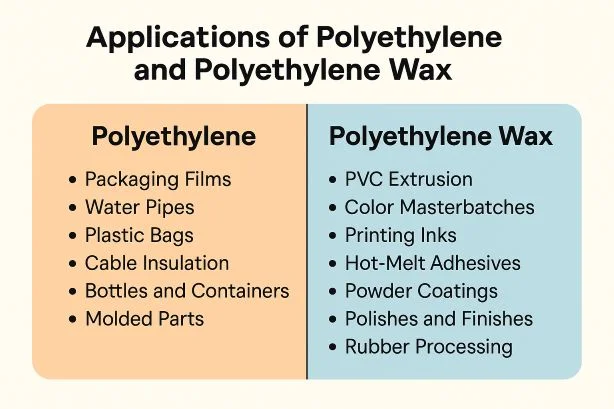

Common Uses of Polyethylene

Because PE offers durability, flexibility, and low cost, it appears in a wide range of products, including:

-

Packaging films

-

Water pipes

-

Plastic bags

-

Cable insulation

-

Bottles and containers

-

Molded parts

Additionally, its chemical resistance makes it suitable for both household and industrial applications.

Common Uses of Polyethylene Wax

PE wax, however, serves more specialized roles. Due to its lubricity and thermal stability, it is used in:

-

PVC extrusion

-

Color masterbatch production

-

Printing inks

-

Hot-melt adhesives

-

Powder coatings

-

Polishes and finishes

-

Rubber processing

Because its melting behavior is predictable, manufacturers rely on PE wax to improve surface quality and processing efficiency.

Role of Polyethylene Wax in Polymer Processing

Internal vs External Lubrication

PE wax acts as both an internal and external lubricant:

-

Internal lubrication reduces melt viscosity, allowing polymers to flow more easily.

-

External lubrication lowers friction between the polymer and metal surfaces, preventing sticking and reducing equipment wear.

As a result, PE wax significantly enhances processing reliability.

Improving Gloss, Flow, and Surface Quality

In addition to lubrication, PE wax boosts:

-

Gloss

-

Slip

-

Scratch resistance

-

Color dispersion

-

Mold release

Consequently, it is considered a performance-enhancing additive in several major polymer industries.

Environmental Impact and Recyclability

Recycling Polyethylene

PE is widely recyclable, especially HDPE (#2) and LDPE (#4). When recycled, it can become:

-

Pipes

-

Containers

-

Film products

-

Plastic lumber

Furthermore, recycling PE reduces environmental impact and supports circular material use.

Recycling Polyethylene Wax

PE wax recycling is more complex. Although it can sometimes be recovered during polymer reprocessing, it is often used in small quantities. Nevertheless, advancements in recycling technologies are improving its recoverability.

For additional insights, visit: https://www.plasticsrecycling.org

Cost Comparison: Polyethylene vs Polyethylene Wax

PE remains cost-efficient because it is mass-produced globally. PE wax, however, costs slightly more due to its specialized production methods. Even so, the amount used per formulation is small, making it economical for large-scale manufacturing.

Choosing the Right Material for Your Application

Choosing between Polyethylene and Polyethylene wax depends heavily on your product requirements. If you need strength, flexibility, and structural stability, PE is clearly the better option. However, if your goal is to improve lubrication, flow, gloss, or dispersion, PE wax is the superior choice. Because both materials complement each other, many manufacturers use them side by side.

Advantages and Disadvantages of Polyethylene and Polyethylene Wax

| Feature | Polyethylene | Polyethylene Wax |

|---|---|---|

| Flexibility | High | Low |

| Lubricity | Low | High |

| Role | Base Material | Additive |

| Melting Point | Higher | Lower |

| Cost | Low | Moderate |

FAQs About Polyethylene and Polyethylene Wax

1. Are Polyethylene and Polyethylene wax the same?

Not exactly. Although they share chemical similarities, their molecular weights and functions differ greatly.

2. Why is PE wax used in plastics?

Because it improves flow, reduces friction, and enhances surface quality.

3. Can Polyethylene wax mix with all polymer types?

It blends well with many plastics, especially PE, PP, PVC, and EVA.

4. Is Polyethylene safe for food contact?

Yes, many grades are FDA-approved for food applications.

5. Does PE wax affect material strength?

No. It mainly affects processing and surface properties, not structural performance.

6. Which one is more expensive?

Polyethylene wax is typically more expensive, although its usage rate is low.

Conclusion

In conclusion, Polyethylene and Polyethylene wax may originate from the same polymer family, yet they serve entirely different roles in manufacturing. PE provides structure, strength, and flexibility, whereas PE wax enhances lubrication, gloss, dispersion, and processing efficiency. Because both materials offer unique advantages, choosing the right one depends entirely on application needs. Ultimately, understanding their differences allows manufacturers to optimize performance, reduce costs, and achieve better-quality products.