Understanding HDPE versus LDPE

When comparing HDPE versus LDPE, it’s important to understand that, although both materials come from the same ethylene monomer, their behavior differs greatly. Because of their unique molecular structures, each material performs differently in strength, flexibility, and durability. Consequently, industries choose them for different reasons.

What Is HDPE?

High-Density Polyethylene (HDPE) is a tough thermoplastic widely used across many industries. Due to its linear and tightly packed molecular structure, HDPE achieves remarkable strength, stiffness, and chemical resistance. As a result, it appears in products that require durability, including pipes, toys, storage containers, detergent bottles, and even fuel tanks.

Table of Contents

ToggleMoreover, HDPE handles pressure and heat better than most common plastics, making it a preferred choice for long-term applications.

What Is LDPE?

Low-Density Polyethylene (LDPE) is another thermoplastic; however, its molecular chains are highly branched. Because of this branching, LDPE becomes significantly more flexible, softer, and lighter. Consequently, LDPE is the go-to material for products that need elasticity, such as plastic bags, films, squeeze bottles, and flexible tubing.

Additionally, LDPE offers good clarity and impact resistance, which is why it dominates the flexible packaging market.

Key Differences Between HDPE and LDPE

Although HDPE and LDPE are both polyethylene types, their performance differs dramatically.

Molecular Structure Comparison

HDPE contains very few side branches, which results in high crystallinity and stiffness. In contrast, LDPE has many side branches, leading to low crystallinity and a softer feel. Thus, their structures directly influence all major physical properties.

Density and Flexibility Differences

HDPE generally has a density of 0.941–0.965 g/cm³, whereas LDPE falls between 0.910–0.940 g/cm³.

Because of this density difference:

HDPE becomes stronger and less flexible.

LDPE becomes softer, more elastic, and more impact-resistant.

Therefore, industries select LDPE for stretchable packaging and HDPE for load-bearing products.

Strength & Durability Comparison

HDPE is naturally stronger and more rigid, which makes it suitable for pressure-resistant applications. Meanwhile, LDPE provides improved cushioning and flexibility. Therefore, if your project requires rigidity, HDPE is the better choice; however, if flexibility matters more, LDPE wins.

Melting Point and Heat Resistance

HDPE: 120–130°C

LDPE: 105–115°C

Given its higher melting point, HDPE performs better in hot environments. Conversely, LDPE deforms more easily under heat, although it still works well in low-temperature applications like food packaging.

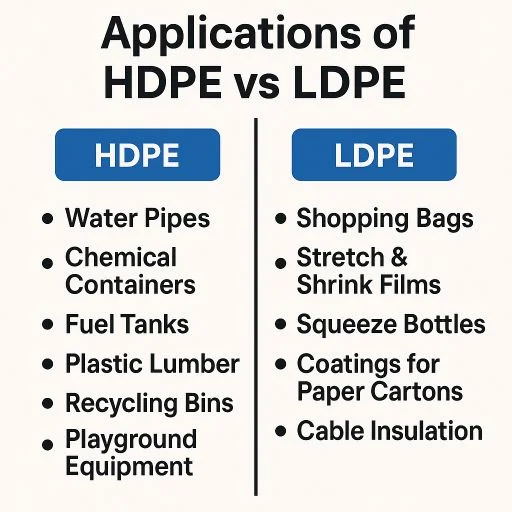

Applications of HDPE versus LDPE in Industry

Everyday Uses of HDPE

HDPE’s strength and rigidity make it ideal for:

Water supply pipes

Food-safe containers

Chemical storage

Plastic lumber

Recycling bins

Playgrounds

Fuel tanks

Furthermore, HDPE is non-toxic and moisture-resistant, which allows it to be widely used in food contact packaging.

Everyday Uses of LDPE

LDPE is highly valued for its flexibility, and for this reason, it appears in:

Grocery bags

Stretch and shrink films

Bread bags

Squeeze bottles

Coatings for paper cartons

Electrical cable insulation

Additionally, because LDPE is lightweight and inexpensive, it remains the preferred material for mass-produced flexible packaging.

Environmental Impact & Recycling

Recyclability of HDPE

HDPE is one of the easiest plastics to recycle. After recycling, HDPE can turn into:

New bottles

Plastic lumber

Crates

Drainage pipes

Storage bins

Thanks to its popularity and recyclability, HDPE contributes significantly to circular plastic economies.

Recyclability of LDPE

LDPE is more difficult to recycle because its thin, flexible structure can clog machinery. Even so, recycling technologies are steadily improving. As more facilities adopt specialized film-recycling equipment, LDPE recycling rates continue to rise.

To learn more, visit: https://www.plasticsrecycling.org

Cost Comparison: HDPE vs LDPE

In terms of cost, LDPE is usually cheaper. Because LDPE requires lower energy during processing and is often produced in large volumes for thin films, it remains budget-friendly. HDPE, however, costs slightly more due to its higher performance and strength.

Even so, HDPE offers excellent long-term value for heavy-duty applications.

Choosing the Right Polymer for Your Application

When choosing between HDPE versus LDPE, your decision should depend on:

Required strength

Temperature exposure

Desired flexibility

Clarity preferences

Cost limitations

Generally, HDPE works best for rigid, load-bearing applications, whereas LDPE excels in flexible packaging and impact-resistant uses. Therefore, understanding your project’s purpose helps you choose the right polymer with confidence.

Advantages and Disadvantages of HDPE versus LDPE

| Property | HDPE | LDPE |

|---|---|---|

| Flexibility | Low | High |

| Strength | High | Moderate |

| Clarity | Low | High |

| Melting Point | Higher | Lower |

| Cost | Moderate | Low |

| Recyclability | High | Moderate |

FAQs About HDPE versus LDPE

1. Which is stronger, HDPE or LDPE?

HDPE is stronger because its molecular chains are more linear and tightly packed.

2. Is LDPE more flexible than HDPE?

Yes. Thanks to its branched structure, LDPE is significantly more flexible.

3. Can HDPE and LDPE be recycled together?

No. Because they melt at different temperatures, they must be separated.

4. Which polymer is safer for food packaging?

Both HDPE and LDPE are considered safe and food-grade.

5. Does HDPE handle heat better?

Absolutely. It has a higher melting point and maintains shape more reliably.

6. Which material is more affordable?

LDPE is typically more affordable because it requires less energy to process.

Conclusion

In summary, the comparison of HDPE versus LDPE highlights how molecular structure influences performance. HDPE provides outstanding strength, durability, and heat resistance, whereas LDPE offers excellent flexibility, clarity, and affordability. Ultimately, your choice should depend on your application’s requirements. By understanding these differences, you can confidently select the polymer that best fits your needs.