What Is Paraffin Wax? – Definition, Types, and Industrial Uses

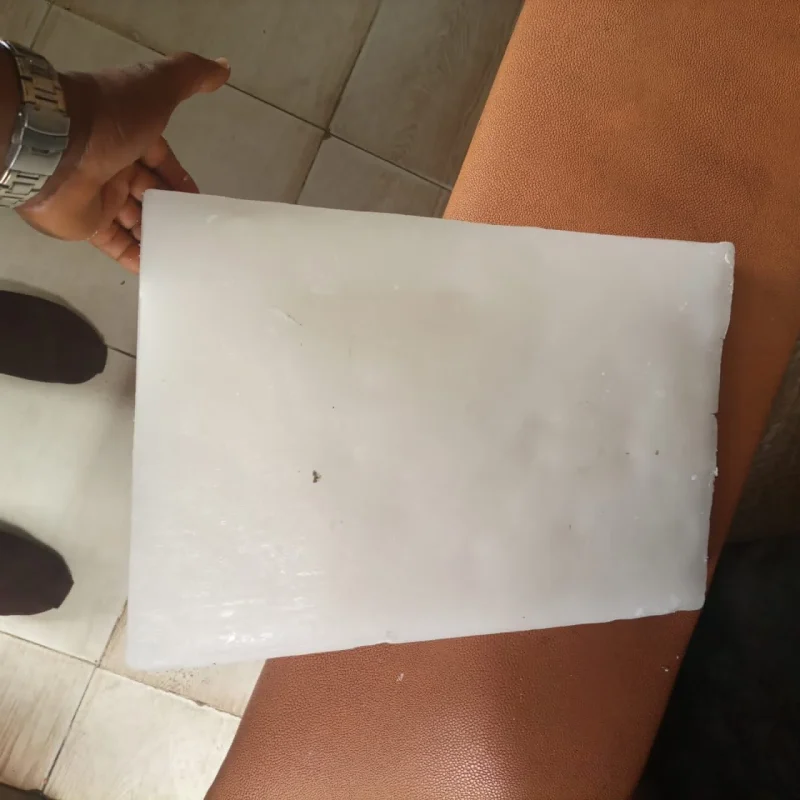

Paraffin wax is one of the most common petroleum-based waxes in the world. It looks white, smooth, and odorless, with a melting point between 46°C and 68°C (115°F–155°F). This wax comes from crude oil refining and serves many purposes, such as in candles, cosmetics, coatings, and packaging. Because it burns cleanly, stores well, and resists moisture, paraffin wax stays one of the most useful materials for both home and industrial production.

How Paraffin Wax Is Made

Refiners create paraffin wax from the heavy parts of crude oil left after distillation. They cool, filter, and separate solid wax from oil. Then they refine it into different grades based on oil content and purity. Fully refined wax contains less than 0.5% oil and appears bright white, while semi-refined wax has 1–3% oil and looks slightly yellow. This refining process ensures a clean, stable, and consistent product that can perform well in various industries. Moreover, producers often adjust filtration and purification steps to achieve the right hardness or melting point for each grade.

Table of Contents

ToggleTypes of Paraffin Wax

Different uses require different wax types. Therefore, manufacturers classify paraffin wax mainly by its melting point.

Low-Melt Paraffin Wax (Below 54°C / 130°F): This soft wax sticks to containers easily, so it is perfect for jar candles and tealights. It melts slowly and produces a smooth, even surface.

High-Melt Paraffin Wax (Above 54°C / 130°F): This hard wax gives structural strength for pillars, molded candles, and industrial coatings. It maintains its form even under warm conditions.

In addition, producers can blend paraffin with microcrystalline wax or additives to improve gloss, flexibility, or stability, depending on the end use.

Why Industries Use Paraffin Wax

Businesses rely on paraffin wax because it is simple to handle, affordable, and steady in performance. It accepts colors and fragrances well and stores safely for months. Moreover, it provides strong water resistance and heat stability. These properties make the wax valuable for coatings, cable filling, packaging, and waterproofing. In addition, it melts evenly and helps create smooth, shiny finishes, which is why it remains the standard material for candle and cosmetic production.

Common Uses of Paraffin Wax

Candle Making: This wax burns cleanly and holds color and fragrance very well. Low-melt wax fits container candles, while high-melt wax works for pillars and molded designs.

Cosmetics and Spa Care: Cosmetic-grade paraffin wax softens skin and locks in moisture. It’s used in hand and foot treatments, lip balms, and creams.

Food and Packaging: Food-grade paraffin protects fruits, cheese, and candies from air and moisture. It adds a glossy surface to chocolates and paper coatings.

Lubrication: The wax reduces friction on drawers, zippers, and metal surfaces. It also prevents rust and improves movement.

Construction and Industrial Use: Paraffin helps waterproof boards, insulate cables, and improve flexibility in rubber and textile products.

Fully Refined and Semi-Refined Grades

Fully Refined Paraffin Wax: With less than 0.5% oil, this type appears clear and odor-free. It’s used for cosmetics, pharmaceuticals, and food packaging.

Semi-Refined Paraffin Wax: This grade contains up to 3% oil and is used for general candles, packaging, and rubber processing.

Both versions remain safe and stable, yet fully refined wax offers better purity and brightness for sensitive applications.

Safety and Environmental Facts

High-quality paraffin wax is non-toxic and safe to use. It burns cleanly when wicks and colors are balanced. Even though it comes from petroleum, modern refining lowers its environmental impact. Additionally, manufacturers can blend paraffin with natural waxes such as soy or palm to make eco-friendly products. Therefore, this material continues to serve as a reliable and safe choice for large-scale manufacturing.

Technical Properties

| Property | Typical Value |

|---|---|

| Appearance | White or colorless solid |

| Melting Point | 46–68°C (115–155°F) |

| Oil Content | 0.3–3% |

| Density @ 20°C | 0.88–0.92 g/cm³ |

| Flash Point | 220–240°C |

| Solubility | Insoluble in water |

Paraffin Wax in the Global Market

Today, paraffin wax remains essential in many production lines because of its low cost, steady supply, and flexibility. It gives products shine, protection, and smooth texture. From candle factories to coating plants, manufacturers prefer this wax for its predictable melting behavior and consistent results. Furthermore, it works well with dyes, perfumes, and additives, allowing endless customization for different industries.

Why Choose IranParaffinWax

IranParaffinWax supplies high-quality fully refined and semi-refined wax for global markets. The company ensures steady production, strict quality control, and fast delivery. It exports paraffin wax in slab, flake, or granule form with packaging options such as 25 kg cartons or PP bags on pallets. Each shipment includes technical documents and certificates to guarantee quality. In addition, IranParaffinWax offers competitive prices and reliable shipping from major Iranian ports to worldwide destinations. Whether for candles, cosmetics, waterproof coatings, or packaging, the company provides a dependable source of refined wax that meets international standards.

Final Thoughts

Paraffin wax remains one of the most trusted materials for both traditional and modern industries. It is clean, safe, and versatile. Moreover, it helps products look better, last longer, and perform more efficiently. When you choose IranParaffinWax, you choose a partner committed to quality, service, and global reliability. Therefore, no matter your production need—candles, cosmetics, coatings, or packaging—this wax continues to deliver consistent performance and lasting value.