Residue Wax Iran

Residue Wax – Industrial Byproduct with Wide Applications

residue wax iran is a cost-effective material that comes from the paraffin wax production process. Because it contains a high amount of oil and wax, industries use it widely in both light and heavy manufacturing. Moreover, its versatility makes it valuable across many markets, from matches to lubricants.

Key Characteristics and Composition of Residue Wax

residue wax iran generally contains 30–40% oil and 60–70% wax. In addition, its flash point falls between 241–255 °C, and its drop melting point stays around 40–45 °C. Furthermore, the color usually varies from yellow to brown depending on production conditions.

Table of Contents

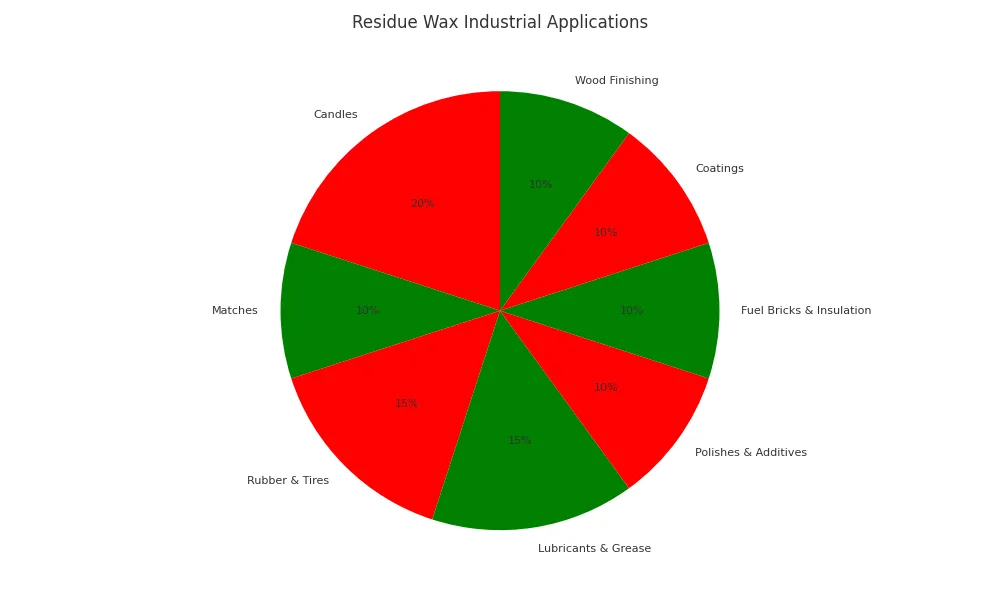

ToggleGlobal Market Uses of Residue Wax in Heavy Industries

Because of its affordability, Residue_Wax attracts heavy industries around the world. It finds roles in candles, fuel bricks, coatings, and insulation materials. As a result, both producers and importers trade it actively in global markets.

Residue Wax in Matches, Rubber, and Tire Manufacturing

Residue Wax plays a vital role in match production because of its flammability. Moreover, rubber and tire industries benefit from its high oil content, which improves flexibility and durability. Therefore, many manufacturers rely on it for consistent performance.

Export Packing Options and HS Code for Residue Wax

Exporters usually pack Residue_Wax in steel drums or second-hand drums to reduce costs. In addition, the HS Code for residue wax iran is 3405.00, which traders use for international classification.

Technical Data and Standard Specifications of residue wax IRAN

-

Oil Content: 30–40%

-

Wax Content: 60–70%

-

Flash Point: 241–255 °C

-

Drop Melting Point: 40–45 °C

-

Color: Yellow to Brown

ResidueWax Supply from Iranian Oil Refineries

Iranian refineries supply Residue Wax in large volumes. Because of their refining capacity, they ensure reliable exports and consistent quality. Furthermore, Iranian suppliers focus on international markets, making them competitive partners for importers.

Economic Importance of ResidueWax in the Wax Chain

residue wax iran reduces waste from the paraffin wax refining process. Instead of being discarded, it enters multiple industries and creates economic value. Consequently, it supports efficiency in the entire wax production chain.

Safety, Handling, and Storage Guidelines for Residue Wax

Industries should store residue wax iran in ventilated areas away from heat. In addition, drums must be sealed tightly to avoid leakage. Workers should also wear protective gloves and clothing to ensure safety during handling.

Residue Wax in Lubricants, Polishes, and Industrial Products

Residue Wax acts as a raw material for lubricants, grease, polishes, and additives. Moreover, it supports rubber industries, shoe manufacturing, and even wood finishing. Because of its broad usage, demand remains strong worldwide.

Contact Us for Residue_Wax Supply

Importers, companies, manufacturers, traders, self-employed people, businessmen, and women are invited to contact us through our website, forum, email, or WhatsApp for competitive offers and reliable supply of residue wax iran.

Analysis of Residue Wax

residue wax iran, contains 30–40% oil content, which gives it a high level of hydrocarbons and makes it suitable for many industrial applications.

In addition, it holds 60–70% wax content, and this balance between oil and solid material increases its flexibility for use in multiple sectors.

Moreover, the color ranges from yellow to brown, and this variation depends on the refining process and source material.

Furthermore, the product shows a flash point between 241–255 °C, which highlights its safety range and defines how industries should handle and store it.

Specification Sheet

Discover the full Residue Wax Data Sheet with detailed specifications, oil/wax composition, and performance values. This technical document helps importers, manufacturers, and traders make accurate decisions with confidence.

MSDS (Material Safety Data Sheet)

Access the Residue Wax MSDS for safe handling, correct storage, and compliance with global standards. Ensure your team and business follow best practices for safe and efficient use.

FAQ 1: What is residue wax iran and how is it different from other waxes?

esidue Wax is a byproduct of the paraffin wax production process. It usually contains 30–40% oil and 60–70% wax, with a yellow to brown color. Unlike fully refined or semi-refined paraffin wax, Residue Wax has a higher oil content, which makes it more suitable for heavy industrial uses like rubber, matches, lubricants, and polishes.

FAQ 2: What are the main industrial uses of Residue Wax?

Residue Wax is widely used in the match industry, tire and rubber production, lubricants, greases, shoe sole manufacturing, and polish formulations. In addition, industries use it in fuel bricks, protective coatings, and impregnation materials because of its oily nature and relatively low melting point.

FAQ 3: How is Residue Wax packed and exported?

residue wax iran is usually packed in steel drums, often second-hand drums that are cleaned for cost efficiency. Exporters use the HS Code 3405.00 for global trade. Because of its oily consistency, it does not require heating during unloading, which makes drums the most practical and economical packing choice.