Iran LDPE producer: Low-Density Polyethylene Uses and Benefits

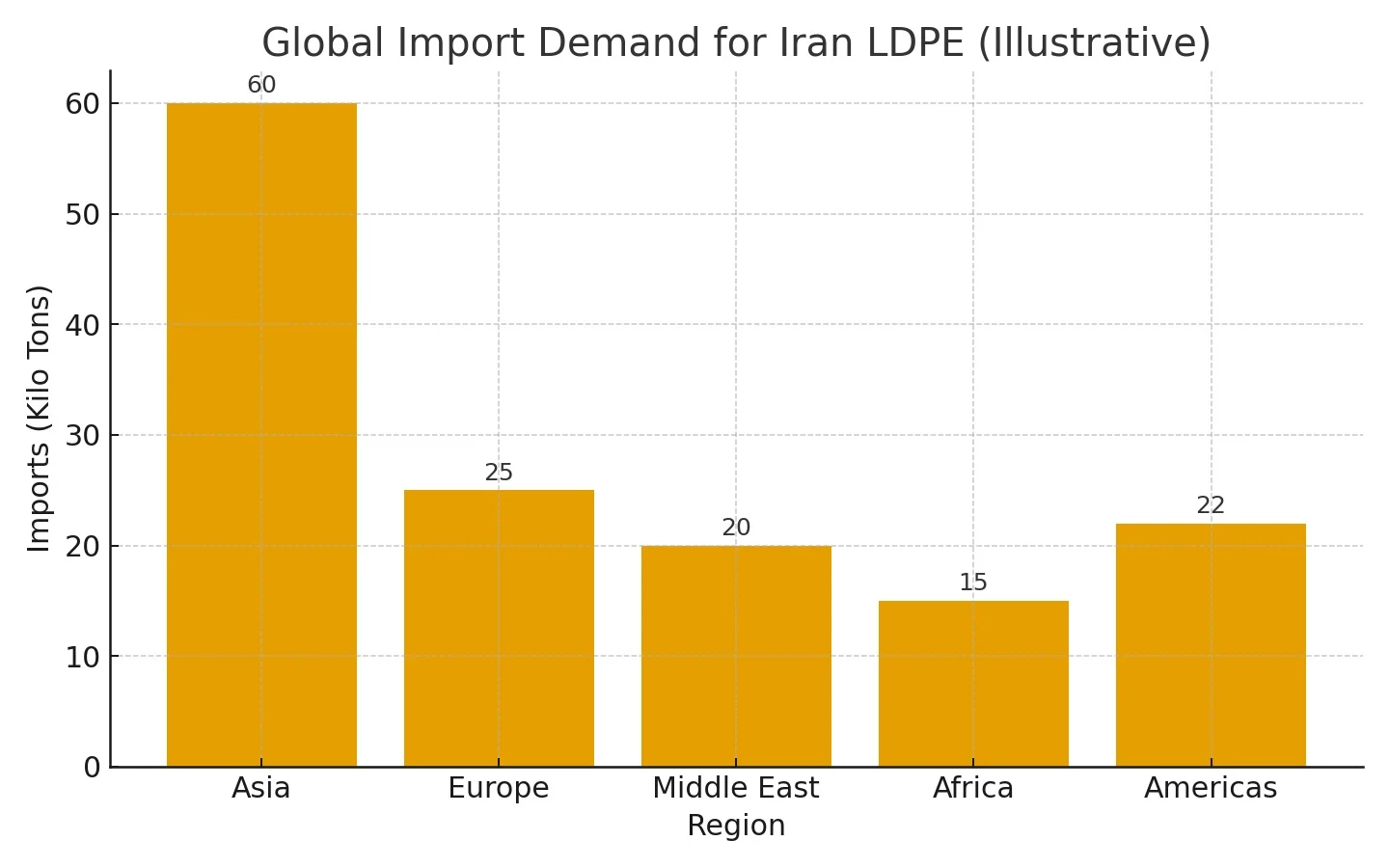

Iran Low-density polyethylene (LDPE) supports industries worldwide because it combines flexibility with durability. It works well in applications that need lightweight yet strong materials. Moreover, manufacturers prefer it because its clean granules make handling, processing, and storage easy. Therefore, LDPE has grown into one of the most demanded polymers across Asia, Europe, Africa, and many other markets.

LDPE Wax – A Specialized Form of Low-Density Polyethylene

Table of Contents

ToggleIran LDPE Wax is a unique material derived from low-density polyethylene that offers excellent lubrication, processing stability, and compatibility with many polymers. Because of its softer structure and lower melting point compared to HDPE wax, it works well in masterbatch production, PVC compounding, coatings, and adhesives. Moreover, its ability to enhance flow and surface finish makes it a popular choice in industries that demand both performance and cost-efficiency. Therefore, global manufacturers in packaging, plastic processing, and rubber industries rely on LDPE wax to improve product quality and optimize manufacturing efficiency.

Industrial Applications of LDPE for Packaging and Films

One of the primary uses of Iran Low-density polyethylene (LDPE) is packaging and films. Because it is both flexible and strong, it performs well in plastic bags, shrink wraps, agricultural films, and liners. Moreover, it protects products while reducing weight, which lowers transportation costs. As a result, manufacturers around the world rely on LDPE to achieve efficient and economical packaging solutions.

Iran LDPE Granules – Versatile Solutions for Global Trade

Iran Low-density polyethylene (LDPE) comes in consistent granules that blend smoothly in production lines. Because of this uniformity, it supports a wide range of industrial processes without disruptions. Moreover, suppliers pack these granules in durable PP bags or jumbo bags for bulk shipments, making storage and handling simple and reliable.

Low-Density Polyethylene from Iran – Specs and Insights

Iran Low-density polyethylene (LDPE) has lower density than HDPE, which gives it greater flexibility and softness. Because of its unique molecular structure, it resists cracking while offering strong processability. Moreover, it performs well in varied temperatures, making it a reliable material for diverse industries that value consistency and durability.

LDPE for Flexible Packaging, Coatings, and Industrial Products

Iran Low-density polyethylene (LDPE) serves many industries beyond films and bags. Because of its chemical stability and flexibility, it supports coatings, insulation, wire covers, containers, and molded parts. Moreover, it processes smoothly, allowing manufacturers to create complex shapes with efficiency and accuracy.

Guide to Iran LDPE for Bulk Buyers and Importers

Bulk buyers prefer Iran Low-density polyethylene (LDPE) because it delivers consistent quality and flexible packaging options. Moreover, Iran’s strategic location reduces shipping time and costs, creating advantages for global buyers. In addition, technical teams help customers choose the right grades for their needs, ensuring that every purchase supports smooth production.

Why Choose Iranian LDPE for Durable, Lightweight Products

Manufacturers choose Iran Low-density polyethylene (LDPE) because it combines durability with lightweight performance. Moreover, its recyclable nature supports eco-friendly production. As a result, businesses can meet market demands efficiently while supporting green initiatives and reducing overall operational costs.

Low-Density Polyethylene for Global Manufacturing Needs

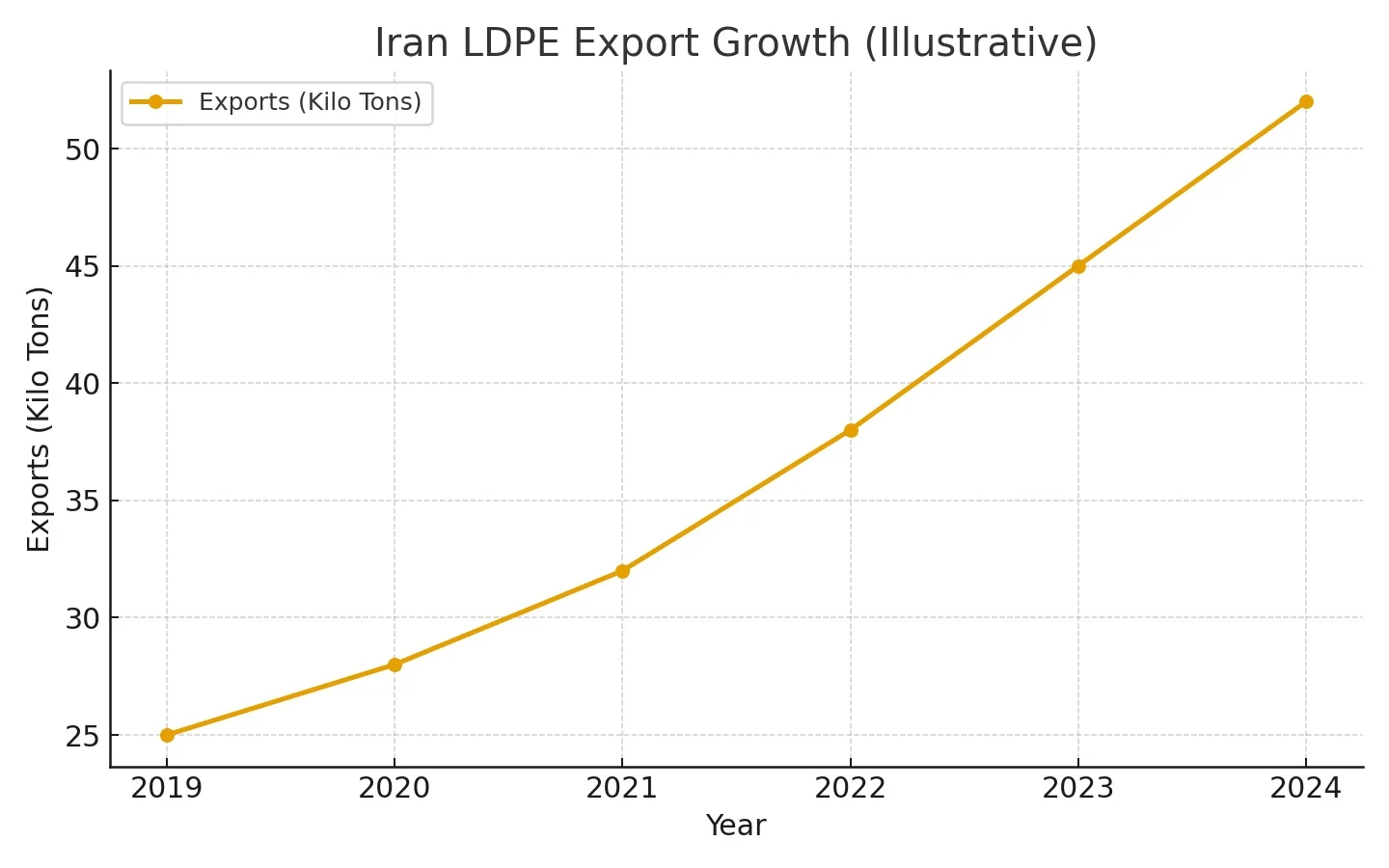

Because Iran Low-density polyethylene (LDPE) is versatile, it supports industries ranging from packaging to automotive, construction, and electrical. Moreover, it performs reliably under demanding conditions, helping manufacturers create quality products consistently. Therefore, demand for Iranian LDPE continues to rise globally.

Iran LDPE Granules – High Quality for Multiple Industries

Producers in Iran maintain strict quality standards, so Iran Low-density polyethylene (LDPE) meets global specifications. Moreover, suppliers offer convenient packaging, such as 25 kg bags or jumbo bags, allowing buyers to plan inventory and logistics with confidence.

LDPE Overview: From Production to Export Solutions

Producers in Iran use advanced technology to create Iran Low-density polyethylene (LDPE) with consistent quality. Moreover, strong production capacity and well-organized export services allow suppliers to fulfill bulk orders quickly. As a result, global buyers rely on Iranian suppliers for steady shipments and dedicated support from order to delivery.

Contact Us Today

If you are an importer, manufacturer, trader, businessman, or businesswoman, contact us today. You can reach us through our website, WhatsApp, email, or forums. Because we value every customer, we respond quickly, share accurate details, and support you through every step of the process.

Low-Density Polyethylene (LDPE) Specification

Because each LDPE grade is designed for specific uses, this table highlights the applications, MFI values, and density levels for every grade. Moreover, this information helps buyers and manufacturers choose the exact type that matches their production iran ldpe producer needs.

| Grade | Application | MFI (gr/10min) | Density (gr/cm³) |

|---|---|---|---|

| 1800 S | This Low-density polyethylene LDPE grade is ideal for caps and closures, sports products, leisure items, and toys because it provides excellent durability and flexibility. | 20.0 | 0.917 |

| 2420 D | This option works best for food-grade bags, pouches, bottles for consumer goods, shrink films, and blown films. Moreover, it supports safe and hygienic packaging needs. | 0.25 | 0.923 |

| 2420 F | This grade performs well for bags, pouches, blow molding applications, shrink films, and blown films, ensuring consistent quality and processing ease. | 0.75 | 0.923 |

| 2420 H | Because of its higher flow rate, this grade is suitable for food-grade films, pouches, shrink films, blown films, and cast films, offering superior performance in packaging. | 1.9 | 0.924 |

| 2420 K | This Low-density polyethylene LDPE grade is designed for coatings, protective films, shrink films, and surface protection films, ensuring durability and excellent surface quality. | 4.0 | 0.924 |

| 2426 F* | This grade is perfect for cast and blown films, food packing films, bags, pouches, shrink films, and protective films. Moreover, the added additives improve performance. | 0.75 | 0.924 |

| 2426 H* | Because of its enhanced properties, this grade fits cast films, bags, pouches, shrink films, blown films, and protective films, meeting high industry demands. | 1.9 | 0.925 |

| 2426 K* | This LDPE grade is a top choice for cast films, food packaging films, shrink films, blown films, and surface protection films, ensuring consistent quality in demanding environments. | 4.0 | 0.925 |

| 3020 F | With excellent balance, this grade is great for bags, pouches, cast and blown films, food packaging, and protective films. Consequently, it supports a wide range of uses. | 0.9 | 0.927 |

| 3020 H | Because of its higher melt flow, this grade excels in cast and blown films, bags, pouches, shrink films, and protective films, offering strength and reliability. | 2.0 | 0.927 |

| 3020 K | This grade Low-density polyethylene LDPE is ideal for cast and blown films, lamination films, and shrink films, ensuring durable and high-quality packaging materials. | 4.0 | 0.927 |

| 3026 H* | This grade suits cast and blown films, bags, pouches, shrink films, and food packaging films, providing excellent stability and durability. | 2.0 | 0.927 |

| 3026 K* | This grade is recommended for cast and blown films, lamination films, shrink films, and food packaging films, ensuring reliable performance and consistent results. |

Specification Sheet

Access the detailed specification sheet for ATDM LDEP including grades, applications, and technical data.

MSDS (Material Safety Data Sheet)

Download MSDS for LDPE to ensure safe handling, storage, and compliance with industry standards.

FAQ 1: What are the main uses of Iran LDPE?

Iran Low-density polyethylene (LDPE) supports many industries because it is flexible, lightweight, and durable. It is widely used in packaging films, plastic bags, agricultural films, shrink wraps, wire covers, insulation, and molded parts. Moreover, its versatility makes it ideal for industries like packaging, construction, and automotive.

FAQ 2: Why do global buyers prefer Iranian LDPE?

Buyers trust Iran Low-density polyethylene (LDPE) because it offers consistent quality, competitive prices, and flexible packaging. Moreover, Iran’s strategic location reduces shipping time and cost, making deliveries faster and more reliable. In addition, Iranian producers follow strict quality checks, ensuring every shipment meets global standards.

FAQ 3: How is Iran LDPE packed for export?

Suppliers pack Iran Low-density polyethylene (LDPE) in 25 kg bags for smaller orders or jumbo bags for bulk shipments. Moreover, this flexible packaging makes storage and handling easy for both small and large buyers. Therefore, importers can manage logistics efficiently while ensuring product safety during transit.