LMP Wax – High-Quality Polyethylene Wax for Industrial Applications

Low Molecular Polyethylene (LMP) is a high-quality polyethylene wax that delivers excellent performance in a wide range of industries. Because it has a balanced viscosity, density, and melting point, it works well in applications that require reliability and consistency. Moreover, manufacturers value LMP wax for its easy handling, efficient processing, and stable quality in every batch.

Premium LMP Wax for Masterbatch, Coatings, and Adhesives

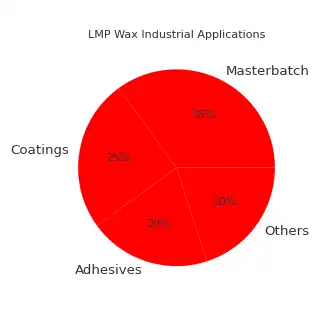

Industries around the world use Low Molecular Polyethylene (LMP) in masterbatch, coatings, and adhesives because it provides smooth dispersion and excellent compatibility. Moreover, it enhances the finish, durability, and overall performance of the final product. Therefore, producers in the plastics, paint, and chemical sectors consider LMP wax a key material for maintaining quality and efficiency.

Table of Contents

ToggleRefined LMP Wax – Reliable Supply for Global Markets

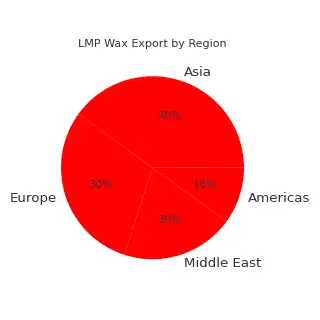

Low Molecular Polyethylene is refined to ensure purity and safe performance. Because every step of production meets international standards, buyers receive a product that is clean, consistent, and high-performing. Moreover, global markets rely on steady supply and competitive pricing, making Iranian LMP wax one of the most trusted options for bulk buyers worldwide.

High-Performance LMP Wax Solutions for Manufacturing

Manufacturers choose Low Molecular Polyethylene (LMP) for its ability to improve production efficiency. Because it melts evenly and blends smoothly, it reduces processing issues and increases output quality. Therefore, businesses in packaging, automotive, and construction industries depend on LMP wax to meet demanding production schedules and deliver premium end products.

Industrial-Grade LMP Wax – Versatile Applications and Benefits

Low Molecular Polyethylene (LMP) offers versatility across many sectors. It supports plastic additives, rubber processing, PVC lubricants, and even wax blends for printing inks and coatings. Moreover, its stable performance under different conditions makes it a reliable choice for both high-volume and specialty applications. Consequently, industries prefer LMP wax when they need both flexibility and consistent performance.

Low Molecular Polyethylene Wax for Packaging, Printing, and Plastic Additives

Packaging and printing industries rely on Low Molecular Polyethylene (LMP) because it improves surface quality, adhesion, and finish. Moreover, plastic manufacturers use it to enhance the strength, durability, and appearance of their products. Therefore, Low Molecular Polyethylene wax plays an important role in producing high-quality goods that meet global standards.

Advanced LMP Wax – Consistent Quality for Bulk Buyers

Bulk buyers prefer Low Molecular Polyethylene (LMP) because of its consistent specifications and reliable supply. Moreover, suppliers offer flexible packaging options, such as 25 kg bags or jumbo bags, to suit different shipping and storage needs. Therefore, importers and manufacturers around the world trust Iranian LMP for stable quality and dependable logistics support.

Low Molecular Polyethylene Wax Specifications and Global Export Opportunities

The specifications of Low Molecular Polyethylene (LMP) include a melting point range of 105–115°C, density around 0.9 ± 0.04 kg/m³, and a flash point above 175°C. Moreover, its low ash and moisture levels make it safe and effective for multiple applications. Therefore, global markets value LMP wax for its quality and competitive pricing, driving steady export growth each year.

Premium Polyethylene Wax – LMP for Industrial Innovation

Because Low Molecular Polyethylene (LMP) supports innovation in many industries, it has become a preferred material for developing new solutions. Whether in advanced coatings, eco-friendly additives, or specialized compounds, Low Molecular Polyethylene wax helps manufacturers meet market demands while improving sustainability and performance.

High-Quality Wax – Reliable, Consistent, and Efficient

Consistency is the key to the success of Low Molecular Polyethylene (LMP). Because each batch is produced under strict quality control, buyers receive reliable results every time. Moreover, its efficiency in processing reduces production costs and ensures high-quality output. Therefore, Low Molecular Polyethylene wax remains a top choice for industries worldwide.

Product Analysis – Low Molecular Weight PE Wax

Molecular weight is above 10,000, ensuring strong and stable performance.

Melting point ranges from 105°C to 115°C, making it fit for many applications.

Flash point stays between 175°C and 190°C, adding safety during processing.

Density is around 0.9 ± 0.04 kg/m³, offering a balanced structure.

Ash content is less than 0.3%, keeping it clean and pure.

Viscosity at 149°C stays between 9.5 and 11.5, ensuring smooth blending.

Moisture level remains below 0.4%, keeping it super dry.

Penetration value is 0.09 ± 0.06 mm, confirming solid consistency.

Appearance shows bright white flakes, dry and easy to handle.

Contact Us Today

If you are an importer, manufacturer, trader, businessman, or businesswoman, we invite you to reach out to us today. You can contact us via our website, email, WhatsApp, or forums. Because we value our clients, we respond quickly, provide detailed product information, and support you through every step of your order process.

Specification Sheet

Access the detailed specification sheet for ATDM Low Molecular Polyethylene (LMP), including grades, applications, and technical data.

MSDS (Material Safety Data Sheet)

Download ATDM’s MSDS for Low Molecular Polyethylene (LMP) to ensure safe handling, storage, and compliance with industry standards.

FAQ 1: What is Low Molecular Polyethylene (LMP) wax used for?

Low Molecular Polyethylene (LMP) wax is used in many industries such as masterbatch, coatings, adhesives, plastic additives, printing inks, and rubber processing. Because it offers smooth dispersion, balanced viscosity, and stable performance, it helps manufacturers improve product quality and efficiency.

FAQ 2: Why do manufacturers prefer Iranian LMP wax?

Manufacturers prefer Iranian LMP wax because it delivers consistent quality, competitive pricing, and reliable global supply. Moreover, it meets international standards, making it a trusted choice for both high-volume and specialized applications.

FAQ 3: How can I order LMP wax in bulk?

You can easily place a bulk order for LMP wax by contacting the supplier through their website, email, WhatsApp, or forums. Moreover, you can request flexible packaging options, such as 25 kg bags or jumbo bags, to match your shipping and storage needs.