Iran LLDPE Wax – High-Performance Linear Low-Density Polyethylene

Linear low-density polyethylene (LLDPE) from Iran stands out because it delivers high strength, flexibility, and consistent quality. Moreover, its unique molecular structure makes it ideal for industries that need reliable performance under varying conditions. Therefore, manufacturers in Asia, Europe, Africa, and the Americas increasingly choose Iranian LLDPE for critical applications.

LLDPE Wax Solutions for Advanced Industrial Applications

Industries worldwide rely on Linear low-density polyethylene (LLDPE) because it blends strength with flexibility. Moreover, it performs well in advanced industrial applications such as film production, lamination, blending, and extrusion. Consequently, it supports everything from simple packaging films to complex multi-layer industrial products with excellent stability.

Table of Contents

ToggleHigh-Quality LLDPE Wax supplier for Blends, Films, and Coatings

Linear low-density polyethylene (LLDPE) is perfect for blown and cast films, coatings, and masterbatch blends. Because it resists tearing and cracking while maintaining clarity and smoothness, it improves both durability and appearance. Moreover, it works well with additives to deliver better performance in demanding environments. As a result, manufacturers achieve higher efficiency and superior product quality.

Iran LLDPE Wax – Specifications, Benefits, and Global Trade

Iranian producers follow strict quality controls for Linear low-density polyethylene (LLDPE). Because of advanced technology and reliable production capacity, every batch offers consistent properties such as a density range of 0.920–0.924 g/cm³ and an MFI range of 1.8–2.2 g/10 min. Moreover, these stable properties make it easy to integrate LLDPE supplier into different industrial processes. Therefore, it has become a preferred product in global trade for its quality and cost-effectiveness.

Why Industries Choose LLDPE supplier for Strength and Flexibility

Many industries choose Linear low-density polyethylene (LLDPE) because it provides strength without losing flexibility. Moreover, it handles a wide range of temperatures, making it reliable in both cold and hot conditions. Therefore, it is an excellent choice for applications that demand consistent performance and durability, including heavy-duty packaging and protective films.

LLDPE Wax for Masterbatch, Packaging, and Polymer Processing

Linear low-density polyethylene (LLDPE) plays a vital role in masterbatch production and polymer processing. Because it blends easily with colorants and other additives, it supports high-quality printing, coloring, and functional performance. Moreover, in packaging industries, it delivers products that are lightweight yet strong, helping companies meet both performance and cost targets.

Global Supply of Iran LLDPE Wax for Industrial Innovation

Iran supplies Linear low-density polyethylene (LLDPE) to markets worldwide because of its reliable production and efficient logistics. Moreover, its competitive pricing and stable quality make it a trusted material for innovators in packaging, construction, and industrial manufacturing. Therefore, global importers rely on Iranian suppliers to keep their supply chains strong and efficient.

LLDPE Wax Overview – From Production to Export Solutions

Producers in Iran use advanced polymerization technology to manufacture Linear low-density polyethylene (LLDPE) that meets global standards. Moreover, they offer flexible export options, including 25 kg bags for small orders and jumbo bags for bulk shipments. Therefore, buyers can plan purchases efficiently while enjoying consistent support for documentation, logistics, and after-sales services.

Performance-Driven LLDPE Wax for Multiple Manufacturing Needs

Because Linear low-density polyethylene (LLDPE) is versatile, it serves many industries, from automotive to agriculture. Moreover, its excellent toughness and tear resistance make it perfect for both light and heavy-duty applications. Consequently, manufacturers choose LLDPE when they want performance-driven materials that deliver long-term value.

Iran LLDPE Wax supplier – Reliable Quality for Global Markets

Iranian Linear low-density polyethylene (LLDPE) maintains consistent quality, making it a reliable choice for buyers worldwide. Moreover, suppliers provide technical support and flexible delivery options, ensuring that every shipment meets the client’s exact specifications. Therefore, businesses can confidently integrate Iranian LLDPE into their production systems for maximum efficiency and value.

Contact Us Today

If you are an importer, manufacturer, trader, businessman, or businesswoman, we invite you to contact us today. You can reach us through our website, WhatsApp, email, or business forums. Because we value your time, we respond quickly, provide detailed product information, and support you at every step of your order process.

Linear Low-Density Polyethylene (LLDPE) and HDPE Specifications

Because Linear low-density polyethylene (LLDPE) is used in many industries, knowing its grades, applications, and technical values is essential. Moreover, these details help buyers and manufacturers select the right type for their specific needs. Therefore, here are the key specifications for LLDPE, LDPE and HDPE products.

LLDPE Grades and Specifications

LL0205 AA – This grade is excellent for heavy-duty sacks, mulch films, stretch films, liners, and geomembranes. Because it offers a melt flow index (MFI) of 0.5 gr/10min and a density of 0.920 gr/cm³, it ensures durability and flexibility for demanding uses.

LL0209 AA – This food-grade material is ideal for heavy-duty sacks, agricultural films, liners, produce bags, and stretch films. Moreover, with an MFI of 0.9 gr/10min and a density of 0.920 gr/cm³, it performs reliably in tough applications.

LL0209 KJ or SR* – Because it is food-grade and includes additives, this grade works well for refuse sacks, produce bags, and carrier bags. Its MFI of 0.9 gr/10min and density of 0.921 gr/cm³ make it a versatile choice for packaging industries.

LL0220 AA – This grade suits light and medium-duty films and stretch films, offering balance and strength. With an MFI of 2.2 gr/10min and a density of 0.920 gr/cm³, it ensures efficiency in production and consistent performance.

LL0220 KJ* – Because it is also food-grade with additives, this option is perfect for light and medium-duty films that need superior clarity and processability. It features an MFI of 2.4 gr/10min and a density of 0.921 gr/cm³.

*Grades marked with an asterisk include additives for improved processing and performance.

Iran LLDPE Supplier – Reliable Source for Quality Polyethylene

Iran has become one of the most trusted LLDPE suppliers in the global petrochemical market. Because Iranian refineries use advanced polymerization technology, they consistently deliver materials that meet international standards. Moreover, every batch of Linear Low-Density Polyethylene (LLDPE) from Iran offers stable density, strong mechanical properties, and uniform melt flow — all essential for reliable industrial performance.

As a result, manufacturers in packaging, film extrusion, and lamination rely on Iranian suppliers for long-term consistency. In addition, these suppliers offer flexible delivery terms, including FOB, CFR, and CIF options, which help importers manage logistics efficiently. Therefore, choosing an Iran LLDPE supplier ensures that you receive premium quality with excellent technical and commercial support.

Furthermore, Iranian LLDPE suppliers provide multiple packaging choices — from 25 kg bags for smaller users to jumbo bags for large-scale buyers — ensuring every customer can purchase exactly what they need. Consequently, global industries view Iran as a dependable hub for high-grade polyethylene supply.

Iran LLDPE supplier Trader – Connecting Global Buyers with Reliable Sources

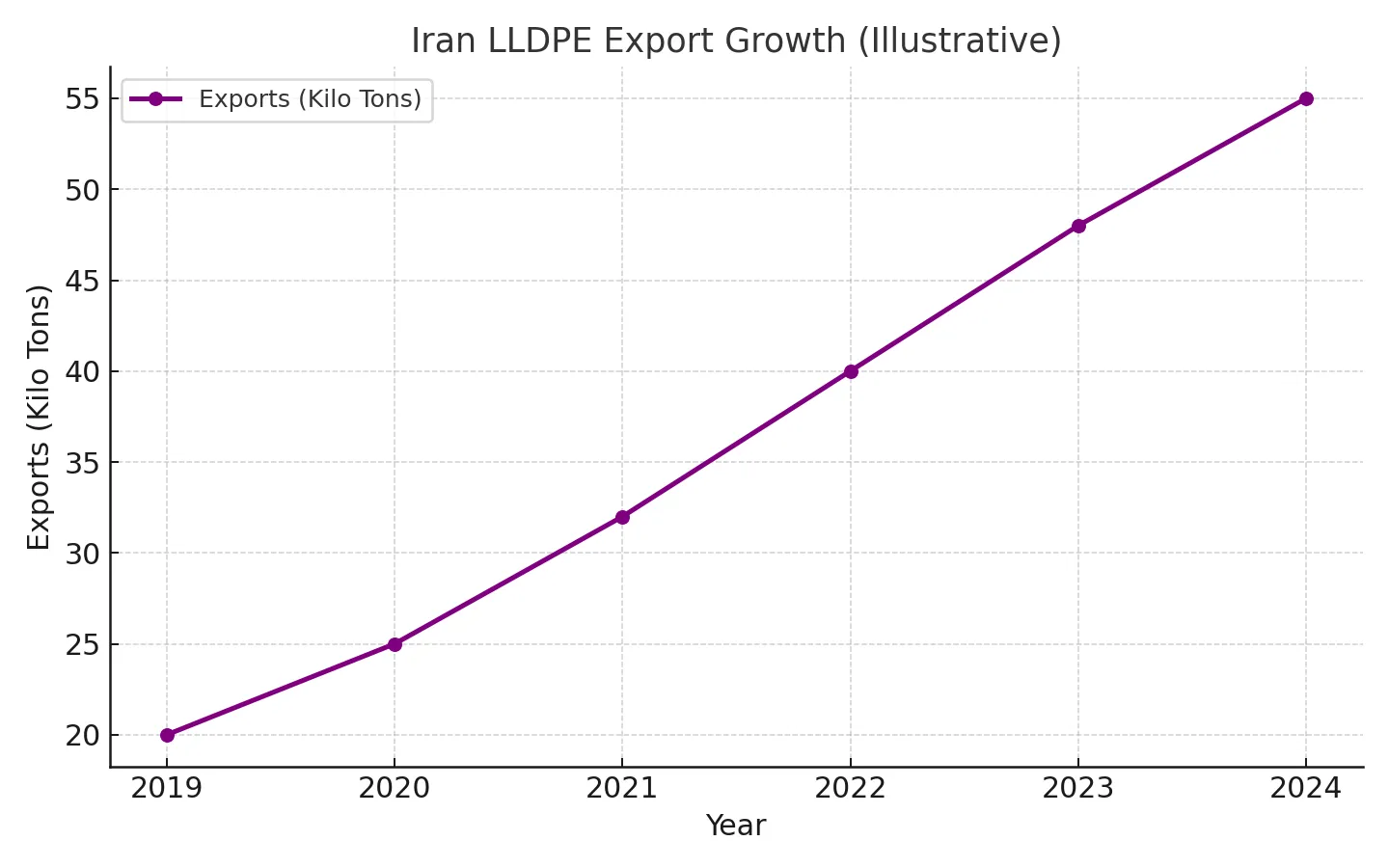

Because international demand for polyethylene continues to grow, Iran LLDPE traders now play a vital role in connecting producers with global buyers. They coordinate between refineries, shipping lines, and end-users to deliver high-performance Linear Low-Density Polyethylene to every continent. Moreover, they ensure competitive pricing and transparent documentation, which greatly simplifies the import process.

In addition, Iranian LLDPE supplier offer extensive market knowledge. They help clients choose the right grade — from LL0205 AA for heavy-duty films to LL0220 KJ for clear packaging. Therefore, manufacturers can optimize production efficiency and material cost simultaneously.

Because these traders maintain close relationships with top Iranian producers, they guarantee fast response times and flexible order handling. Consequently, customers worldwide rely on Iran LLDPE traders for steady supply chains, timely delivery, and continuous technical support.

Iran LLDPE supplier Exporter – High-Performance Polyethylene for Global Markets

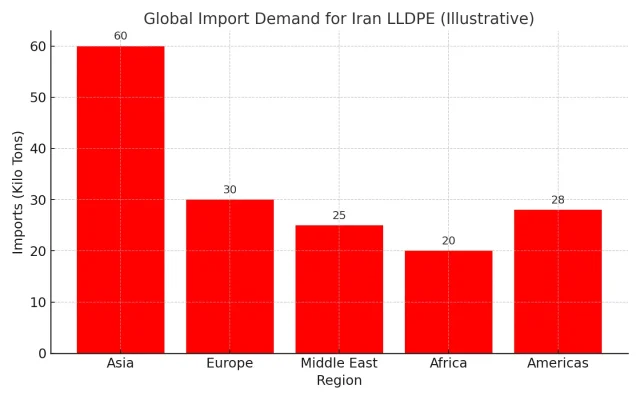

Iran has established itself as a leading LLDPE exporter, delivering premium materials to Asia, Africa, Europe, and the Americas. Thanks to large production capacity and modern refineries, Iranian exporters provide consistent quality that meets both local and international specifications. Moreover, they offer efficient logistics through major ports such as Bandar Abbas and Bushehr, ensuring smooth global shipments.

In addition, Iranian LLDPE exporters provide full export documentation — including Certificate of Analysis, Technical Data Sheet, and Safety Data Sheet — which helps importers clear customs easily. Furthermore, their experience with long-term contracts and flexible payment terms allows international buyers to plan procurement confidently.

Therefore, choosing an Iran-based exporter means gaining access to high-purity Linear Low-Density Polyethylene that combines flexibility, strength, and process stability. As a result, global customers continue to prefer Iranian suppliers for their commitment to reliability, transparency, and value.

Iran LLDPE Wax – High-Performance Linear Low-Density Polyethylene

Linear Low-Density Polyethylene (LLDPE) from Iran offers the perfect balance of strength, flexibility, and cost efficiency. Because Iranian producers use advanced polymerization techniques, each shipment delivers uniform properties that suit extrusion, lamination, and blending operations. Moreover, the product’s toughness and clarity make it ideal for packaging, film production, and coating applications.

In addition, Iranian LLDPE wax performs exceptionally well when blended with other polymers or additives, improving processability and mechanical strength. Consequently, industries worldwide prefer Iranian LLDPE for sustainable production and long-term performance.

Furthermore, Iran’s strategic location near major shipping routes enables exporters to deliver quickly to Asia, Europe, and Africa. Therefore, global manufacturers benefit from steady supply, technical reliability, and competitive pricing.

Specification Sheet

Access the detailed specification sheet for Linear low-density polyethylene (LLDPE), including grades, applications, and technical data.

MSDS (Material Safety Data Sheet)

Download ATDM’s MSDS for Linear low-density polyethylene (LLDPE) to ensure safe handling, storage, and compliance with industry standards.

FAQ 1: What are the main uses of Linear low-density polyethylene (LLDPE)?

Linear low-density polyethylene (LLDPE) is used in many industries because it combines strength and flexibility. It is ideal for blown and cast films, lamination, blending, coatings, masterbatch, and packaging. Moreover, it performs well in heavy-duty applications, such as agricultural films and industrial liners, making it a versatile material for global markets.

FAQ 2: Why do buyers prefer Iranian LLDPE?

Buyers choose Iranian Linear low-density polyethylene (LLDPE) because it offers consistent quality, reliable supply, and competitive pricing. Moreover, Iranian producers follow strict quality checks and use advanced production technology to meet international standards. Therefore, global importers trust Iranian suppliers for smooth delivery and dependable performance.

FAQ 3: How is LLDPE packed for export?

Suppliers pack Linear low-density polyethylene (LLDPE) in 25 kg bags for smaller orders or jumbo bags for bulk shipments. Moreover, this flexible packaging makes storage and handling easier while reducing overall shipping costs. Consequently, importers can manage their logistics more efficiently and keep their production lines running smoothly.